Work Smarter, Not Harder

Everyone has heard the age-old saying, “Work smarter, not harder.” Nowhere is this concept more applicable than as a result of the Internet of Things’ aptitude for automating and communicating manual tasks.

Tracking the daily measurements of seemingly unchanging interior spaces can be terribly tedious. Yet when large, heavy equipment begins shifting positions, the demand for action is imperative, and the precision (or lack thereof) of measurements can be game changing.

Recently, one of my clients was faced with this exact dilemma. Steel slag used to backfill a factory construction site had reacted with groundwater and caused heaving in the factory floor.

As the floors moved, machines fell out of alignment. Constant recalibration slowed production. And because the problem lay beneath the factory foundation, the client had virtually no means of addressing it.

We couldn’t stop the floors’ heaving, but we could monitor it. And with accurate data, we could correct tiny shifts before they negatively impacted production.

I was originally brought onto the project to oversee the manual measuring of the facility’s walls, floors and equipment. It didn’t take long for my team and me to realize that there had to be a better way—and we knew it had to involve automation.

So, I put on my thinking cap, and I sat in my thinking chair, and I wrote in my thinking notebook. And with help from my team, I came up with a new plan—a “smart” plan.

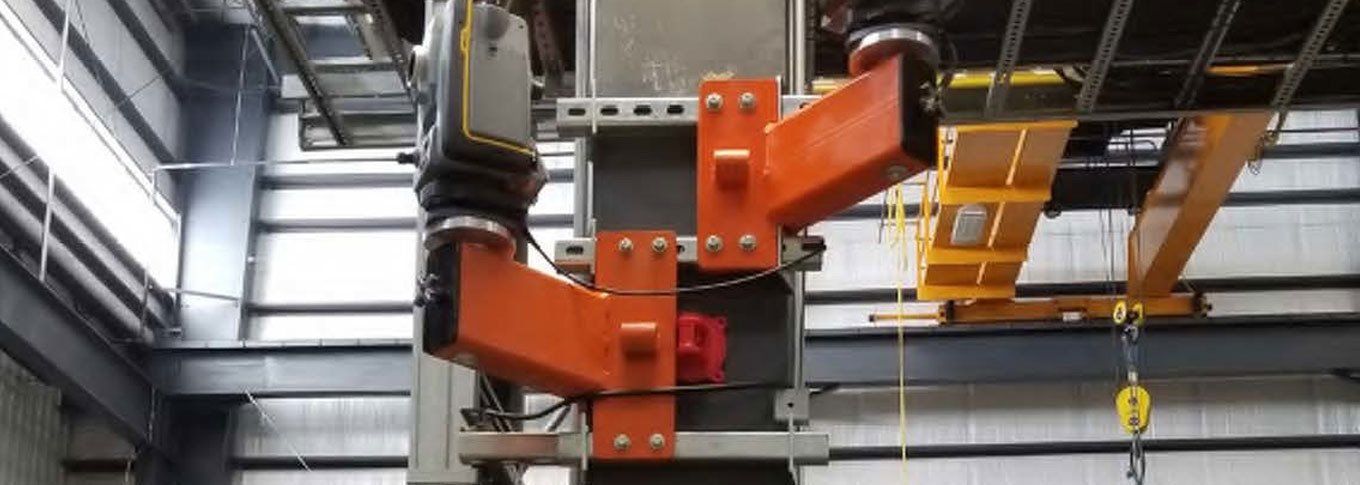

Using our patent-pending mounting bracket, we attached Trimble robotic total stations to factory columns at identified measurement locations throughout the factory. Then, we set up a wireless network to collect and transmit measurements (according to a set schedule) to a secured server for storage and reporting.

Now, instead of sending crews to the project site daily to collect measurements, I can review extremely accurate data from the convenience of my desk and report results directly to my client in near-real time.

Not only does this approach save my team tremendous time, it also saves the client money—a lot of money. And, by removing the element of human error, the measurements are more precise than ever before.

With spot-on, sub-millimeter accuracy, our automated measurement system quickly alerts my client to even minute shifts in machinery placement, floor level or wall plumb. Adjusting the machinery and evaluating structural integrity has transformed a reactive response to a proactive effort.

Better results don’t necessarily take more effort—they take better, smarter effort.